Unveiling the Cost of Silicon

Introduction: Understanding the Expense

Silicon, a fundamental element in modern technology, carries with it an associated cost that impacts various industries. To comprehend the expense of silicon, one must delve into its production processes and market dynamics.

Production Process: Energy-Intensive Methods

The production of silicon involves intricate processes, notably extraction, purification, and crystallization, all of which demand significant energy inputs. The primary method, known as the "Siemens process," entails high-temperature furnaces and substantial energy consumption.

Market Dynamics: Supply and Demand

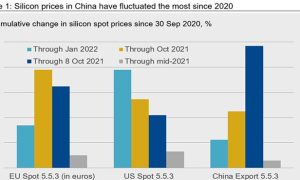

The cost of silicon is subject to the forces of supply and demand, alongside factors such as production costs and technological advancements. With increasing demand from industries like electronics and solar energy, silicon prices may fluctuate accordingly.

Price Range: Reflecting Market Realities

As of the latest data, the cost of silicon typically falls within a range of $0.50 to $1.50 per pound. However, this price range is influenced by various factors including purity level, production method, and market conditions. Prices may vary based on factors such as quantity, quality, and supplier.

Applications: Impact on Affordability

Silicon's affordability is deeply intertwined with its diverse applications across industries. From semiconductors and solar panels to construction materials and medical devices, silicon's versatility drives demand and thus affects its pricing.

Conclusion: Grasping the Expense

In conclusion, the cost of silicon is influenced by complex factors including production processes, market dynamics, and application demand. To explore more about the cost of silicon, visit cost of silicon for further insights.